Drive-In Pallet Rack

Highest Density Storage for Fast Moving SKUs

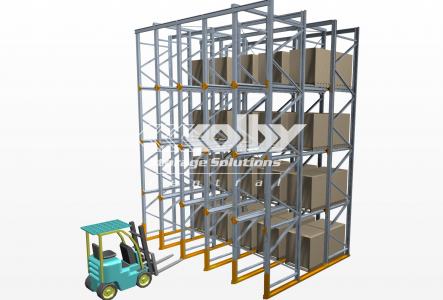

Drive-In Rack is the lowest cost and most popular form of high density pallet racking. It can be serviced by a variety of forklifts including counterbalance and reach trucks

Providing excellent storage capacity, Colby Drive-in Pallet Racking (sometimes called Drive-through racking) uses the storage principle that the first pallet in is the last pallet out.

Drive-In pallet racking is a continuous block of racking with no aisles, offering high density storage, typically for non-perishables.

Advantages:

- Offers almost double the storage capacity over selective methods

- High density storage system dependant on product mix

- Relatively low capital cost in comparison to other high density solutions

- Used with standard forklift trucks

- Last in first out principal (LIFO)

Average of locations used - efficiency:

75%

Immediate access to stored product:

25%

Stock Rotation:

Poor

Floor Utilisation:

65%

Benefits of the Colby Drive-In Rack System:

- “Lead-in” nose and heavy-duty floor channel design help guide the forklift, ensuring quick and easy alignment with the pallet

- Ensures safer handling and protection of the rack with stronger, more rigid uprights

- Optimised, wider design increases strength and stability

- Available in either 125mm or 150mm wide versions and a range of thicknesses.

- Innovative Cantilever Brackets adjustable in 50mm increments for optimum storage flexibility.

- Unique, strong one piece design ensures there is negligible rotation under load

- Single-sided design provides the versatility of setting different pallet levels in adjacent bays

- New patented design is capable of large spans, minimising vertical deflection and virtually eliminating horizontal deflection and twist

- Securely bolted from underneath, avoiding any catchpoints and adjustable at 50mm intervals for greater flexibility in frame depth