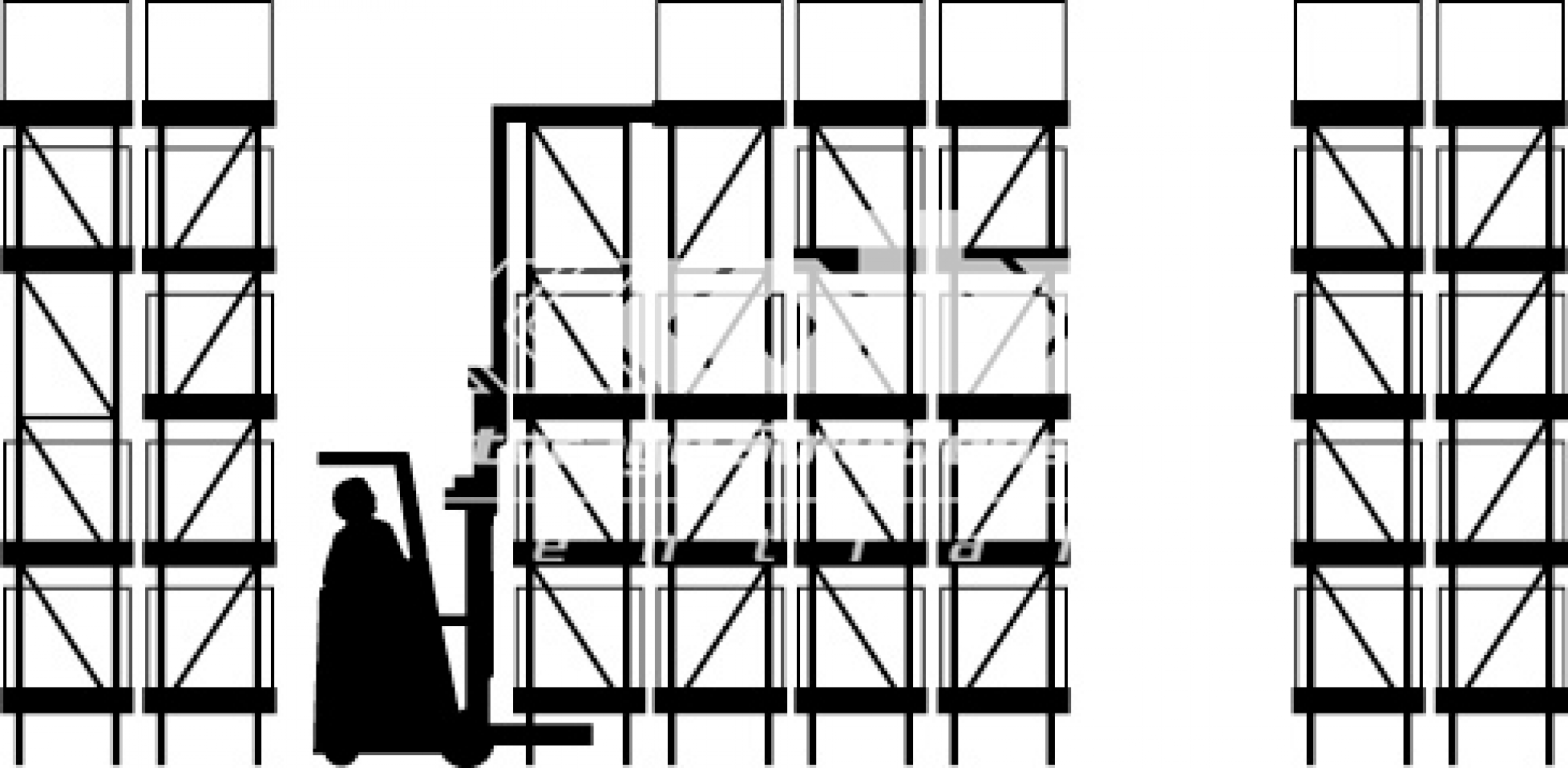

Double Deep Pallet Racking

Although not a truly selective system, Double Deep Racking offers many companies a cost effective method of bulk storage. Access and stock rotation is compromised compared to Selective Pallet Racking,

However cube utilisation is much higher. Specially designed forklifts use a variety of doubledeep reach mechanisms to allow easy placement and retrieval of pallets.

Storing pallets two-deep for better capacity:

- Double deep racking stores two pallets deep in a single entry rack or four pallets deep in a double entry rack.

- This system requires the use of a special reach fork lift truck with either dual pantograph or sliding fork attachments.

- Double deep racking improves storage density with fewer aisles and more storage locations. This reduces the aisle to rack ratio but also reduces selectivity (FIFO).

- Truck lift heights are limited by load, to about 9 metres.

- The upper levels can be fitted with front to back guide rails to assist the operator to locate and place a pallet at height. The bottom beam must be sufficiently clear of the ground to allow the reach trucks legs to pass under it.

Features:

- Storage density increased as rack aisle ratio changes from selective racking.

- 50% immediate accessibility with reasonable stock rotation.

- Good use of all available locations, typically 90%.

- Safe and secure handling with the bottom pallet usually off the ground.

- Ability to use double deep handling equipment for other tasks.

- Best used when each SKU has several pallets.

Advantages:

- Greater use of available headroom

- Good access to 50% stock locations

- Enables stock rotation

- Efficient in operation

- Relatively low cost racking system

- 40% increase in storage capacity

Average of locations used - efficiency:

90%

Immediate access to stored product:

50%

Stock Rotation:

Average

Floor Utilisation:

60%